3D UV dryer up to 150 W/cm

Sold

3D UV dryer up to 150 W/cm

Location:North Rhine-Westphalia, Germany

Description

Only 2 instead of 4 radiation modules !

The radiation modules are installed at an angle, but straight (not pivoted as usual),

therefore it is possible to realize a 3D drying with only one radiation module.

The special reflector design and geometry ensures that the radiation is completely

and reaches the substrate.

With the multifocus reflector geometry, several focus lines are generated in the space between the UV module and the substrate.

the UV module and the substrate / workpiece.

Thus, parts of different heights can be safely irradiated without changing the height of the UV module.

This means that in the first radiation module a gallium emitter could be mounted and

a mercury emitter in the second radiation module. Other combinations are also possible.

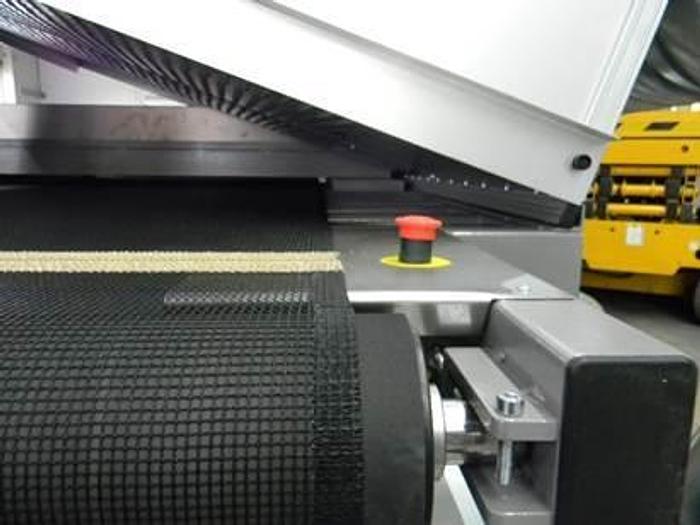

- Transport system with net belt, PTFE coated (optional, bar conveyor possible).

Equipment:

- UV- Power-Control, microprocessor controlled power regulation of the UV lamps (True RMS).

- Stepless UV power control (30-100 % ), most modern processor control and regulation

of the UV radiation power for an exactly reproducible UV radiation (quality assurance).

- Environ -Multireflection

- Super Cure- quality UV lamps with longer lifetime.

- Slider technology to open and close the module

- Controlled reflector cooling, FU controlled heat extraction with additional cooling air supply.

- Automatic material detection (with standby function on approx. 10% UV power).

- Controller processor Modicon with color touch display.

- Frequency converter with CANopen connection to PLC.

Specifications

| Year | 2006 |

| Condition | New |

| Stock Number | 0,00 |

| Product code | 3308228 |

| Radiation systems | 2 pieces |

| Working width | 1.300 mm |

| Uv emitter length | 1.500 mm |

| Uv radiant power | max. 150 Watt/cm |

| Uv power control | stepless from 30% to 100% |

| Radiation spectrum | Mercury vapor medium pressure emitter, 1 x Ga, 1 x Hg |

| Additional reflector | Reflector system for mounting below a conveyor |

| Reflector cooling | Controlled reflector cooling with exhaust and supply air |

| Reflector design | Environ -Multireflection |

| Lens hood | Environ auxiliary reflector with cooling function |

| Master frame | UV module mounting, alignment for edge irradiation |

| Uv radiation protection | Integrated in master frame |

| Energy saving function | Automatic stand-by circuit with power reduction to approx. 10% . |

| Total length transport system | 3.0 m |

| Delivery up | 900 mm + - 25 mm |

| Passage height/part height | about 100 mm |

| Electrical connection | 400V~, 50 Hz, 3-phase +N +PE |